KP 510A Vision Added Automatic Printer

- Apply to SMT/Semiconductor Stencil/ Screen printing, also for the solder paste printing/ glue printing process.

- Repeat printing could achieve to ±10μm.

- On-axis light and ring lamp to be used, could check for different types of PCB board.

- Floating blade and constant pressure system; control the printing pressure accuracy on each position.

- Precise clamping system can effectively overcome the printing accuracy for curved PCB.

- Auto stencil cleaning which is included functions of wet wiping, dry wiping and exhausting the air.

| NO | Machine Information |

|---|---|

| Approx dimension(D*W*H) | 1688*1370*1945mm |

| Approx weight | About 1000Kg |

| Power supply | AC 1Ø,220V,50/60HZ;3.5kw,15A |

| Air supply | Clean dry air 5~6kg/cm2 30L/min |

| Operation interface | Windows XP |

| Board Specification | |

| Suitable dimension of board | max:400*310(mm) min:50*50(mm) |

| Suitable thickness of board | 0.6~6(mm) |

| Board width adjustment | Auto |

| Suitable weights of board | 3kg or less |

| Board clamping tooling | Edge clamp (Could adjust the softness) |

| Print Parameters | |

| Stencil frames | 650*550~736*736mm,T=30~35mm |

| Print area | 310*400mm |

| Print pressure | 0.5~5kg/cm2 |

| Stencil separation speed | 0.1~5mm/sec (Programmable) |

| Print pitch | -1~5mm(Programmable) |

| Print direction | Front to back/Back to front |

| Print speed | 5~200mm/sec |

| Vision System | |

| CCD camera | High resolution CCD |

| Image process | Multi binary control |

| Fiducials | 2 |

| Fiducial spec | 0.1mm~3.0mm |

| Fiducial position | Any point on PCB |

| Fiducial error recovery | Auto fiducial search |

| Machine Capability | |

| Repeat Precision | ±10μm |

| Printing precision | ±20μm |

| Cycle Time | 7.5sec + Printer times |

| Clean function | Wet wiping/Dry wiping/Exhaust the air |

| Clean dimension | X:400mm |

| Change without notice. Welcome customized request. |

|

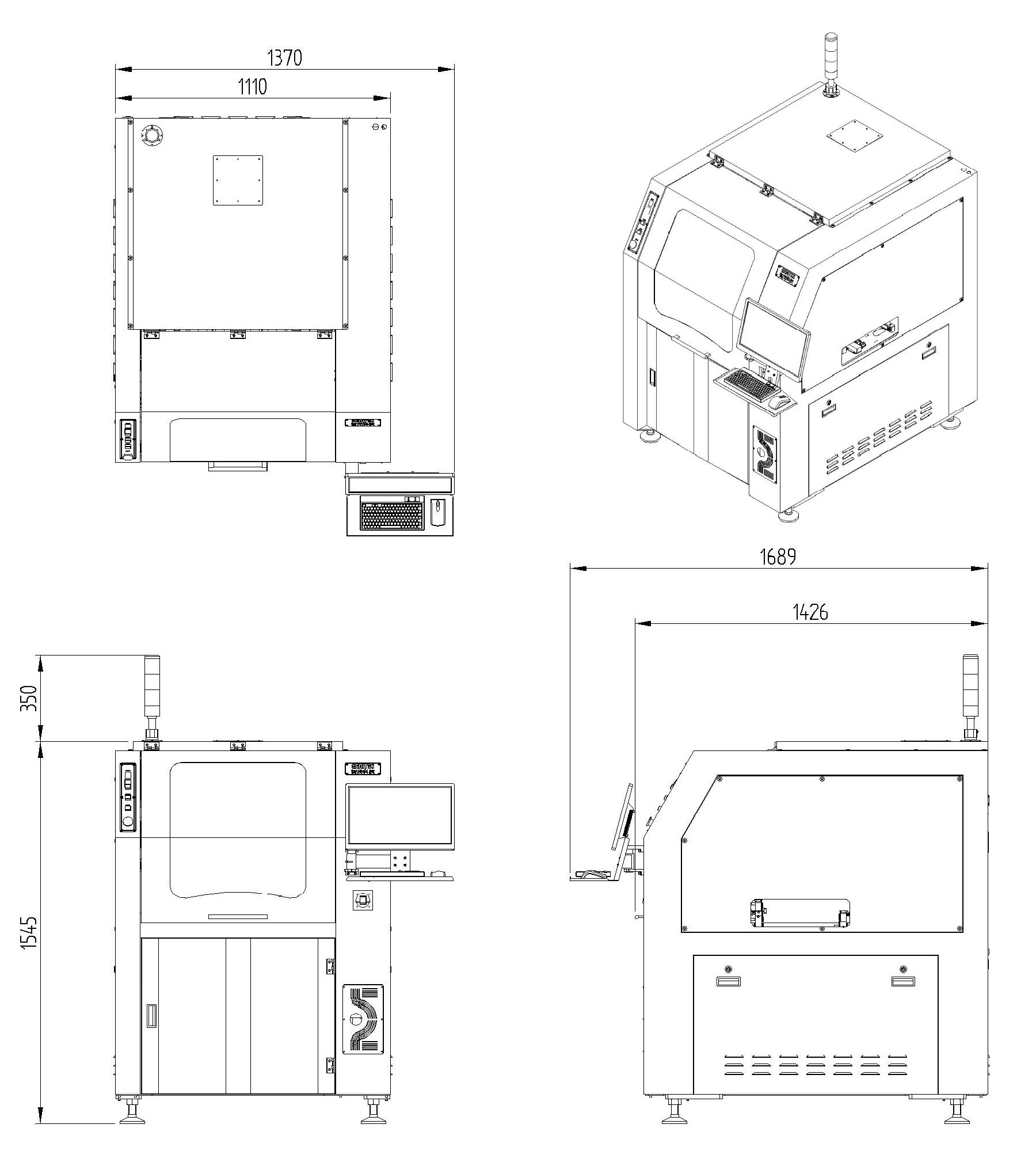

Dimension

| NO | Machine Information |

|---|---|

| Approx dimension(D*W*H) | 1688*1370*1945mm |

| Approx weight | About 1000Kg |

| Power supply | AC 1Ø,220V,50/60HZ;3.5kw,15A |

| Air supply | Clean dry air 5~6kg/cm2 30L/min |

| Operation interface | Windows XP |

| Board Specification | |

| Suitable dimension of board | max:400*310(mm) min:50*50(mm) |

| Suitable thickness of board | 0.6~6(mm) |

| Board width adjustment | Auto |

| Suitable weights of board | 3kg or less |

| Board clamping tooling | Edge clamp (Could adjust the softness) |

| Print Parameters | |

| Stencil frames | 650*550~736*736mm,T=30~35mm |

| Print area | 310*400mm |

| Print pressure | 0.5~5kg/cm2 |

| Stencil separation speed | 0.1~5mm/sec (Programmable) |

| Print pitch | -1~5mm(Programmable) |

| Print direction | Front to back/Back to front |

| Print speed | 5~200mm/sec |

| Vision System | |

| CCD camera | High resolution CCD |

| Image process | Multi binary control |

| Fiducials | 2 |

| Fiducial spec | 0.1mm~3.0mm |

| Fiducial position | Any point on PCB |

| Fiducial error recovery | Auto fiducial search |

| Machine Capability | |

| Repeat Precision | ±10μm |

| Printing precision | ±20μm |

| Cycle Time | 7.5sec + Printer times |

| Clean function | Wet wiping/Dry wiping/Exhaust the air |

| Clean dimension | X:400mm |

| Change without notice. Welcome customized request. |

|