GAM 336AT In-line Automatic PCB Router Machine

The flexible single transferring can pick & place PCBA in 0-180 angle which can satisfy the demand of its prior and back process.

Use CCD to do the vision positioning off-set and alignment which can ensure the precision in cutting.

Equipped with high-speed ESD spindle for function of auto tool-change to reduce the PCBA damage due to static.

The patent design of its flexible brush can split router bit's blade into several sections for production which can extend its life cycle.

3 options of unloading products, belt, conveyor, fixture or the customization placing tray process.

GAM336AD and GAM 336ALD PCB router machines equipped with high efficiency dual spindles are also available.

| GAM 336AT | GAM 336AL | |

|---|---|---|

| Valid cutting size | 350*300mm | 450*420mm |

| Loading Method | Track Delivery | |

| Unloading Method | Conveyer belt or track Delivery (optional) | |

| Movement Direction | Left to Right or Right to Left(optional) | |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc | |

| Process table | Dual tables | |

| Repeat precision | ±0.01mm | |

| Cutting precision | ±0.05mm | |

| Max moving speed | XY:1000mm/sec , Z:800mm/sec | |

| Spindle's speed | MAX: 60000rpm (Adjustable) | |

| Tool change type | Auto tool change | |

| Cutting speed | 1-100mm/s | |

| Operating system | Windows 10 | |

| Program teaching mode | Intuitive teaching by CCD color image input | |

| Control method | Precision multi-axis control system | |

| XYZ axis driving mode | AC Servo motor | |

| Size of milling tool | ∮0.8-3.0mm | |

| Voltage/Power requirement | AC220V 50/60HZ 4Kw 1Φ | |

| Pneumatic pressure requirement | 0.6MPa, 200L/min | 0.6MPa, 220L/min |

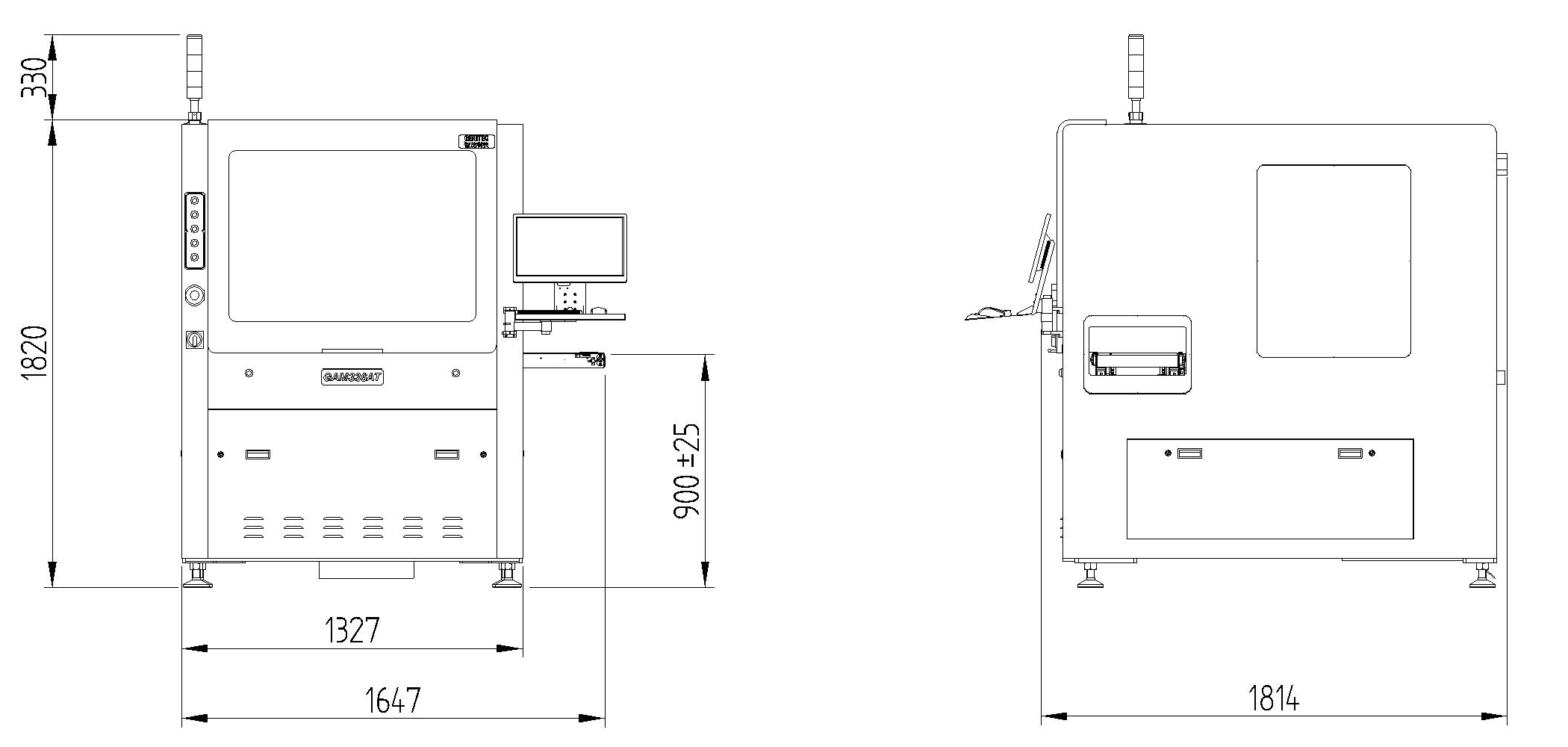

| Dimensions(W*D*H) | 1647*1814*1820mm | 1947*2096*1820mm |

| Weight | 835公斤 | 1145公斤 |

| Dust collector | TS300L | |

| Change without notice. Welcome customized request. The customization unloading's placing tray and cutting detection will make specifications different due to the modification. |

||

- Cutting detection module.

- The height checking module in laser.

- Barcode reader.

- Milling tool diameter detection.

- The customized MES.

Front View/Side View

| GAM 336AT | GAM 336AL | |

|---|---|---|

| Valid cutting size | 350*300mm | 450*420mm |

| Loading Method | Track Delivery | |

| Unloading Method | Conveyer belt or track Delivery (optional) | |

| Movement Direction | Left to Right or Right to Left(optional) | |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc | |

| Process table | Dual tables | |

| Repeat precision | ±0.01mm | |

| Cutting precision | ±0.05mm | |

| Max moving speed | XY:1000mm/sec , Z:800mm/sec | |

| Spindle's speed | MAX: 60000rpm (Adjustable) | |

| Tool change type | Auto tool change | |

| Cutting speed | 1-100mm/s | |

| Operating system | Windows 10 | |

| Program teaching mode | Intuitive teaching by CCD color image input | |

| Control method | Precision multi-axis control system | |

| XYZ axis driving mode | AC Servo motor | |

| Size of milling tool | ∮0.8-3.0mm | |

| Voltage/Power requirement | AC220V 50/60HZ 4Kw 1Φ | |

| Pneumatic pressure requirement | 0.6MPa, 200L/min | 0.6MPa, 220L/min |

| Dimensions(W*D*H) | 1647*1814*1820mm | 1947*2096*1820mm |

| Weight | 835公斤 | 1145公斤 |

| Dust collector | TS300L | |

| Change without notice. Welcome customized request. The customization unloading's placing tray and cutting detection will make specifications different due to the modification. |

||