GAM 320AT In-line Automatic PCB Router Machine

Automatic operation from loading, cutting and un-load PCBs, we offer lots of solutions to meet process requirements.

Use CCD to do the vision positioning off-set and alignment which can ensure the precision in cutting.

Use high-speed spindle for cutting with auto tool-change function to reduce PCBA damage due to static.

Patent flexible cleaning brush enables the milling tool to be used in sections then extend the life of it.

There are others high efficiency types are assembled with dual spindles, such as model no. GAM320AD, GAM 330AD and GAM340AD for customer’s selection.

| GAM320AT | |

|---|---|

| Valid cutting size | 350*300 mm |

| Loading Method | Track Delivery |

| Unloading Method | Belt Delivery or Track Delivery |

| Transfer Method | Vacuum nozzle absorption |

| Movement Direction | Left to Right or Right to Left |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc |

| Process table | Dual tables |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving speed | XY: 1000mm/sec, Z: 800mm/sec |

| Max moving trip | X: 790mm Y: 440mm, Z: 90mm |

| Spindle's speed | MAX: 60000rpm (Adjustable) |

| Tool change type | Auto tool change |

| Cutting speed | 1-100mm/s (Adjustable) |

| Operating system | Windows 10 |

| Program teaching mode | Intuitive teaching by CCD color image input |

| Program backup | USB data transfer |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | ∮0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60HZ 4Kw 1Φ |

| Pneumatic pressure requirement | 0.6MPa, 155L/min |

| Dimensions(W*D*H) | 1949*1192*1705 mm |

| Weight | 750KG |

| Dust collector | TS200L |

| Change without notice. Welcome customized request. |

|

- Optional clamping module for carrier process.

- The height checking module in laser.

- Barcode reader.

- Milling tool diameter detection.

- The customized MES.

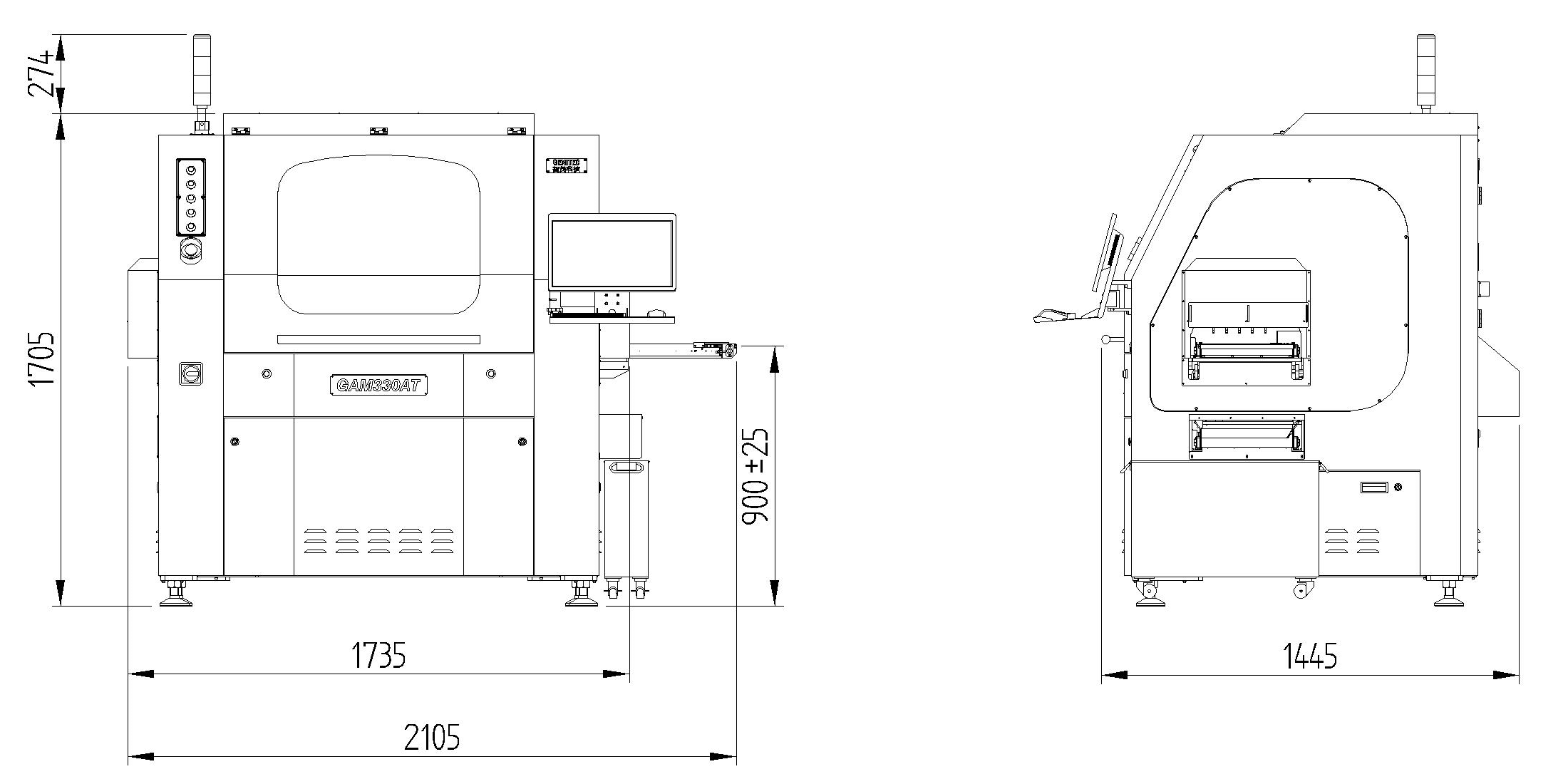

Front View/Side View

| GAM320AT | |

|---|---|

| Valid cutting size | 350*300 mm |

| Loading Method | Track Delivery |

| Unloading Method | Belt Delivery or Track Delivery |

| Transfer Method | Vacuum nozzle absorption |

| Movement Direction | Left to Right or Right to Left |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc |

| Process table | Dual tables |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving speed | XY: 1000mm/sec, Z: 800mm/sec |

| Max moving trip | X: 790mm Y: 440mm, Z: 90mm |

| Spindle's speed | MAX: 60000rpm (Adjustable) |

| Tool change type | Auto tool change |

| Cutting speed | 1-100mm/s (Adjustable) |

| Operating system | Windows 10 |

| Program teaching mode | Intuitive teaching by CCD color image input |

| Program backup | USB data transfer |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | ∮0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60HZ 4Kw 1Φ |

| Pneumatic pressure requirement | 0.6MPa, 155L/min |

| Dimensions(W*D*H) | 1949*1192*1705 mm |

| Weight | 750KG |

| Dust collector | TS200L |

| Change without notice. Welcome customized request. |

|